News & Blog

Management Spotlight: Kerry Kearney

Tech Etch has more than five decades of expertise and experience engineering flexible printed circuits, EMI/RFI shielding, and thin metal components. In this management spotlight, we’ve turned our focus to

Why are ESG Policies Important

ESG, or environmental, social, and governance policies are an increasingly important part of the business landscape. These policies focus on a company's impact on the environment, its treatment of employees

Tech Etch Announces New Shielding Solutions: UL94 V-0 Certified 2400 and 2500 (Halogen Free) Series Fabric Over Foam

PLYMOUTH, MA – November 6th, 2023 – Tech Etch, an industry leader in precision-engineered thin metal components, EMI/RFI shielding, and flexible printed circuits, is excited to unveil their latest innovation

Innovation Spotlight: Tech Etch’s 2500 Series Fabric Over Foam

The Tech Etch 2500 Series UL94 V-0 Certified Halogen Free Fabric Over Foam presents a refined integration of design precision and technological capabilities. With its specific material characteristics and wide

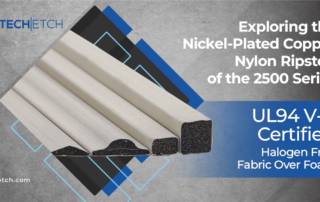

Exploring the Nickel-Plated Copper Nylon Ripstop of the 2500 Series UL94 V-0 Certified Halogen Free Fabric Over Foam

In the realm of EMI shielding, the choice of fabric is not about aesthetics or basic functionality. It is about pushing the boundaries of innovation and optimizing performance. Enter the

Representative Kathleen LaNatra Visits Tech Etch to Present 8th Annual “Manufacturer of The Year” Award

## FOR IMMEDIATE RELEASE ## PLYMOUTH, MA – October 12th, 2023 – Tech Etch, a prominent 100% employee-owned manufacturer of EMI/RFI Shielding solutions, precision parts and flexible circuits is honored