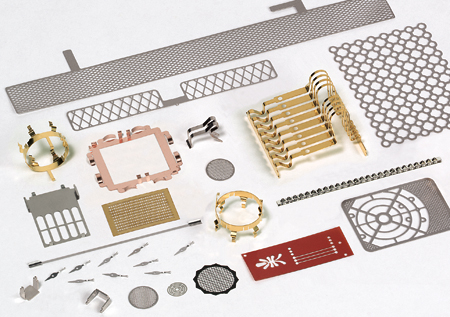

Discover Our Material Options For Precision Parts

Along with photo etching, we offer laser cutting, forming, plating, laminating, and stamping on thicker metals.

Different parts call for different materials. When you work with Tech Etch, you can get the mechanical or electronic parts you need, made out of the best materials for the job.

We specialize in photo etching (also known as photochemical milling) using materials like Tungsten, Elgiloy™, Nitinol, Molybdenum, Titanium, and Kapton® (polyimide film). These materials are especially useful in the medical industry for cathodes, springs, implants, blades, and stents. Our parts can be manufactured as thin as .0005 inches.

Our team can also photo-etch parts with other metals including Copper Alloys, Beryllium Copper, Stainless Steels, Aluminum, Nickel and Nickel Alloys, Silver, Spring Steel, Iron Alloys, Kovar, and Inconel.

Photo etching is a great way to go about creating parts out of metal. The process offers:

- Flexibility in manufacturing small and large quantities

- Low cost due to lack of need for expensive tooling

- Quick turnaround times from design to production

WE CAN ETCH ALMOST ANYTHING

Have a material not listed below, contact us to inquire.

See below to find out more about a few materials we already work with.

Standard Materials

- High electrical conductivity

- Malleable

- Easily etched

- Easily plated or soldered

- Formability both with and across grain

- Preferred alloys CDA 110, 101, and 102

- Easily photoetched

- Heat treatable

- Good Electrical conductivity – due to 22 to 66% copper content

- Tensile strength to 200,000 psi attainable (temper sensitive)

- High fatigue strength

- Excellent formability to tight tolerances – both with and across grain (temper sensitive)

- Corrosion resistance

- Easily soldered or plated

- Easily resistance welded

- Alloy C172 is the most common

- High corrosion resistance

- The 300 series is most common

- Available in the 400 series

- Available in the precipitation hardening alloys (17-7PH)

- Etch quality is less than copper and ferrous alloys (due to grain structure)

- Can be anodized

- Can be iridited

- High thermal and electrical conductivity

- Light weight

- Preferred forming alloy 5052 H32 and H34

- Silvery appearance (contains no silver)

- Copper, zinc and nickel alloy

- High environmental corrosion resistance

- Easily soldered, formed or plated

- Stronger and more durable than copper

- Nonmagnetic

- Easily photoetched

- Easily etched

- Low spring back

- Easily plated

- Formability both with and across grain

- Less tensile strength than BeCu

- Preferred alloy CDA 260

- Copper, tin and phosphorous alloy

- High tarnish, corrosion and fatigue resistance

- Excellent spring properties

- Easily formed or soldered

- Lower electrical conductivity compared to copper

- Iron, cobalt and nickel alloy

- Excellent thermal properties for many applications

- CTE similar to that of glass or ceramic

- Susceptible to rust if not plated

- Can be plated in a variety of materials

- Great mechanical properties

- Low cost

- Many different grades and alloys available

- Easily welded

- Durable and shock resistant

- Nickel-chromium superalloy

- Phenomenal temperature resistance

- Excellent corrosion resistance at all temperatures

- Higher tensile strength than stainless steel (depending on alloys)

- Perfect for extreme applications or environments – rapid temperature changes, saltwater, etc.

Specialty Materials

Tungsten is 71 percent heavier than lead and therefore is very useful in a wide range of medical uses. Tungsten has become a go-to metal for:

- Collimating and attenuating stray x-rays in CT scanners

- Creating ID tags used in implanted medical devices

- Providing filaments in vacuum and x-ray tubes

- Functioning as heating elements and nozzles

As a refractory material, molybdenum is ideal for high temperatures and corrosive environments.

One of the toughest metals out there, titanium is lightweight and highly resistant to corrosion. It can be used in everything from eyeglass frames to jet engines. Titanium is inert and biocompatible, making it perfect for use in a variety of medical applications, such as maxillofacial and craniofacial reconstruction plates. It’s also a useful metal for anode and cathode battery current collectors and telemetry antennas.

We can create a wide range of products out of titanium, customizing the parts to your specifications.

When you need a material that is very highly corrosion resistant and is strong against fatigue, Elgiloy™ is the best option. This metal is commonly used in medical implants, and Tech Etch can create the pieces you need for your specific use.

For high-temperature environments, you can’t go wrong with Kapton®. This material shows good physical, chemical, and electrical properties when exposed to a wide variety of temperatures, including extreme heat.

Tech Etch uses photo etching to make flat parts for a wide range of applications, including screens, gaskets, washers, insulation layers, and more. Kapton® is a registered trademark of Dupont.

Niobium offers corrosion resistance under high temperatures. It’s a lightweight, refractive material that is ductile and easily formed.

If you need a shape memory alloy, Nitinol is a great option. As the “memory foam” of the metal world, its unique characteristics allow it to return to its original shape after deformation. This material has high corrosion resistance and excellent biocompatibility, as well as good spring characteristics.

- Tech Etch offers laser cutting of thin Tantalum parts

- Excellent corrosion resistance, especially in acids and caustics

- Strong and highly ductile

- Biocompatible