General Information

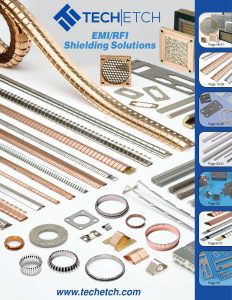

When mesh EMI shielding is all you need, turn to Tech Etch. We can supply you with knitted wire mesh made of Monel™, TCS (tin-plated copper-clad steel), stainless steel, or aluminum. When choosing material, consider corrosion resistance, mechanical characteristics, and attenuation potential. Get spools or coils of the material, or request a specific cut with or without end seals.

Standard profiles include round, round with tail, double round with tail, half-round, and rectangular. Most of our profiles can be purchases as all-mesh, and all options are available with elastomer cores to enhance compression and increase deflection range.

Specifically, Monel is the trademark name for a series of alloys mostly made up of nickel and copper, with some iron and other trace elements. Monel alloy 400 exhibits the same proportions of nickel and copper, found naturally in the nickel ore from certain mines. Other grades of Monel include 401, 404, K-500, and R-405. The additions of other metals and slight changes in characteristics are what differentiate these grades; K-500, for example, includes small additions of aluminum and titanium.

Monel is known for its corrosion resistance, but the specific properties and applications of each type vary:

- Monel 401 – Often used in electrical and electronic applications, it has a very low temperature coefficient of resistance.

- Monel 404 – Its composition is specifically adjusted for low temperature, low permeability, and good brazing. It is often used for electronics due to its low permeability.

- Monel R-405 – This alloy includes a controlled amount of sulfur, which provides sulfide inclusions that act as chip breakers during machining. It is often used for screw-machine products, fasteners, and valve parts.

- Monel K-500 – This alloy has the same corrosion resistance as Monel 400, but with even greater strength and hardness. Like Monel 404, it has low permeability. It is often used for oil well tools, instruments, pump and marine propeller shafts, doctor blades, scrapers, and more.