General Information

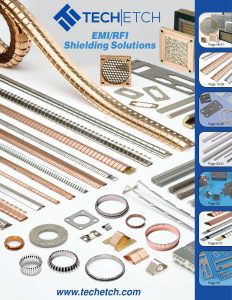

Shielding strips are required by a wide range of industries for a variety of applications. When you need standard EMI shielding strips, think of Tech Etch.

Our RoHS-compliant shielding strips are available in lengths of 16” to 24”, in continuous coils of up to 35 feet, as individual fingers, or cut to customized full-finger lengths.

Our uncompressed standard finger stocks range from .03” to .44”. These can fill gaps that are as small as .01”. Most of our products are available in two thicknesses to meet your specific requirements. Whether you need standard or TF gaskets, you can count on us for top-quality products.

Speak with our engineering department today to discuss special modifications.

BERYLLIUM COPPER EMI SHIELDING PRODUCTS

STAINLESS STEEL EMI SHIELDING PRODUCTS

CUSTOM DESIGNED EMI SHIELDING

BERYLLIUM COPPER EMI SHIELDING PERFORMANCE

| H-Field – 100kHz | E-Field – 10MHz | P-Field – 1GHz |

|---|---|---|

| >110 dB | >110 dB | <110 dB |

Note: Plating the mating surfaces with the same material will provide superior performance. Chromate chemical film on aluminum maintains surface conductivity by reducing corrosion.

EMI SHIELDING COMPATIBILITY

ELECTROMAGNETIC COMPATIBILITY

EMI/RFI Shielding Products are designed to either keep out or keep in electromagnetic interference. Shielding reflects and absorbs incident radiation. The higher the attenuation of the shielding, the more effective it is at keeping in or out the undesired electromagnetic interference.

ELECTROCHEMICAL COMPATIBILITY

To avoid galvanic action between contacting metals refer to this chart. Materials in adjacent groups may be safely used together. Choosing materials from within a single group in the table will provide the least corrosion due to galvanic action when the materials are in contact for an extended period of time with appropriate protective finish.

GROUPING OF METALS BY DECREASING GALVANIC ACTIVITY

| Group 1 | Group 2 | Group 3 | Group 4 |

|---|---|---|---|

| Magnesium | Aluminum | Cadmium Plating | Brass |

| Magnesium Alloys | Aluminum Alloys | Carbon Steel | Stainless Steel |

| Aluminum | Zinc & Zinc Plating | Iron | Beryllium Copper |

| Aluminum Alloys | Chromium Plating | Nickel & Nickel Plating | Copper & Copper Alloys |

| Zinc & Zinc Plating | Cadmium Plating | Tin & Tin Plating | Nickel/Copper Alloys |

| Chromium Plating | Carbon Steel | Tin/Lead Solder | Monel |

| Iron | Brass | Silver | |

| Nickel & Nickel Plating | Stainless Steel | ||

| Tin & Tin Plating | Beryllium Copper | ||

| Tin/Lead Solder | Copper & Copper Alloys | ||

| Nickel/Copper Alloys | |||

| Monel |